Planet

Top Cement Tech Innovations to Watch in 2025 for Sustainable Construction

As the world continues to grapple with the urgent need for sustainable construction practices, the focus on innovative cement tech has never been more critical. In 2025, advancements in cement technology are poised to redefine the construction landscape, offering solutions that not only enhance structural integrity but also reduce environmental impact. This article delves into the most promising innovations in cement tech that are set to emerge, showcasing how they can contribute to eco-friendly building practices.

The significance of integrating sustainability into construction cannot be overstated, especially as urbanization accelerates and the demand for resilient infrastructures grows. With the cement industry being one of the largest contributors to carbon emissions, the development of greener alternatives and manufacturing techniques is essential. In this context, innovations in cement tech—ranging from alternative materials to energy-efficient production methods—are crucial for addressing the challenges posed by climate change while meeting global construction needs.

By embracing these cutting-edge advancements, the construction sector can align itself with the principles of sustainability, paving the way for a future where cement tech not only supports building longevity and safety but also champions an environmentally responsible ethos. This exploration of emerging trends highlights the importance of investing in research and development to foster a more sustainable built environment.

Innovations in Cement Production: Reducing Carbon Emissions by 30% by 2030

As the construction industry faces increasing pressure to mitigate its carbon footprint, innovations in cement production are at the forefront of achieving these sustainability goals. Recent reports indicate that the cement sector contributes approximately 8% of global carbon dioxide emissions, highlighting the urgent need for transformative solutions. By 2030, the aim is to reduce these emissions by 30%, and various innovative techniques are being explored to make this a reality.

One promising approach is the development of alternative clinker materials. Traditional Portland cement relies heavily on limestone, which generates significant CO2 during production. Innovations in the use of industrial byproducts, such as fly ash and slag, can significantly reduce reliance on limestone and subsequently lower emissions. According to a report from the International Energy Agency, integrating these materials could lead to a reduction of around 15% in CO2 emissions per ton of cement produced. Coupled with advancements in carbon capture and storage technology, which are projected to become more economically viable by 2025, the goal of reducing emissions from cement production is increasingly within reach.

Moreover, the rise of digital technologies in cement production is set to transform operations. By utilizing data analytics and machine learning, manufacturers can optimize production processes, enhance energy efficiency, and minimize waste. The Cement Sustainability Initiative notes that smart manufacturing techniques could improve efficiency by up to 20%, further contributing to emission reduction efforts. As these innovations unfold, the cement industry is poised to make significant strides toward sustainability, laying the groundwork for a greener construction future.

Top Cement Tech Innovations to Watch in 2025 for Sustainable Construction

Advancements in Alternative Materials: Incorporating 15% Recycled Content in Cement

The construction industry is increasingly recognizing the need for sustainable practices, and one of the most promising innovations on the horizon is the incorporation of recycled content in cement. By integrating 15% recycled materials into cement production, companies can significantly reduce their carbon footprint while still maintaining the structural integrity needed for various architectural applications. This advancement not only minimizes the demand for virgin raw materials but also helps divert waste from landfills, creating a circular economy within the construction sector.

Moreover, the shift towards alternative materials in cement production is facilitated by advancements in recycling technologies and a better understanding of material properties. This allows for the use of industrial by-products, such as fly ash and slag, which can be effectively repurposed as supplementary cementitious materials. By leveraging these innovations, the industry can produce high-performance cements that contribute to more environmentally friendly building practices without sacrificing quality. As manufacturers adopt these methods, the focus will be on optimizing compositions that enhance strength and durability, ensuring that sustainable options are not only feasible but desirable for modern construction needs.

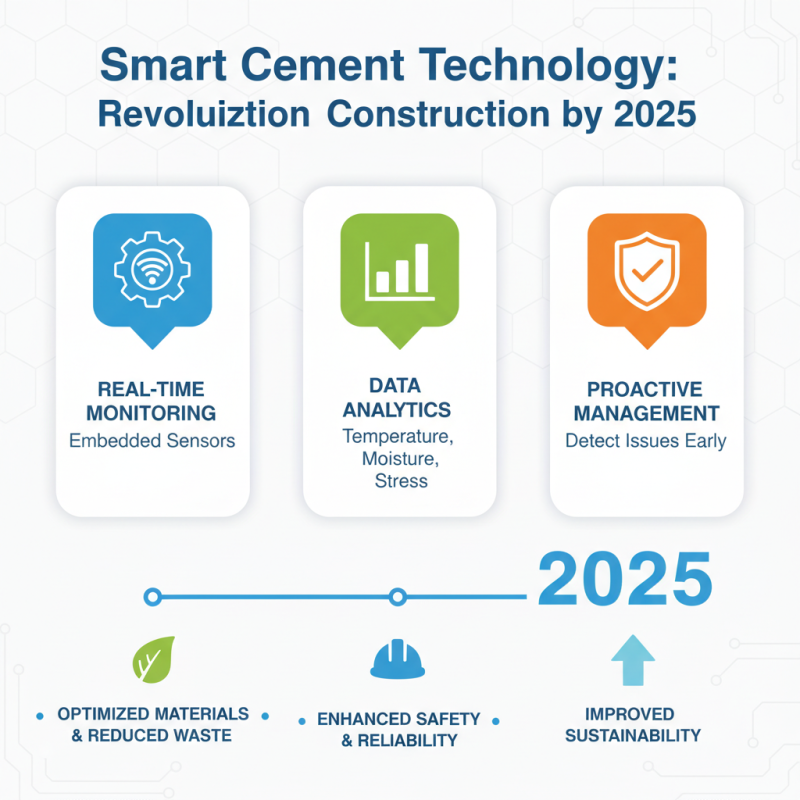

Smart Cement Technology: Real-time Monitoring and Data Analytics in 2025

Smart cement technology is poised to revolutionize the construction sector by 2025, with a strong focus on real-time monitoring and data analytics. This innovative approach allows for the continuous assessment of cement's condition during the curing process, enabling contractors to detect issues such as structural weaknesses or uneven curing rates before they escalate into costly problems. Embedded sensors within the cement can provide vital information on temperature, moisture levels, and stress, allowing for a more proactive management of construction projects. This technological integration not only enhances the safety and reliability of structures but also optimizes the use of materials, reducing waste and improving overall sustainability.

Data analytics plays a crucial role in leveraging the insights gathered from smart cement technology. By analyzing the data collected through sensor networks, construction teams can make informed decisions throughout the project lifecycle. Predictive analytics can forecast potential failures or maintenance needs, thereby extending the lifespan of structures while ensuring compliance with environmental standards. Moreover, these advancements empower builders to tailor their construction methods to local conditions, ultimately leading to more resilient and sustainable infrastructures. The shift towards data-driven cement technology underscores a broader commitment to reducing the carbon footprint of construction practices and embracing innovation in the pursuit of eco-friendly building solutions.

Energy Efficiency in Cement Plants: Targeting 25% Reduction in Energy Use

Energy efficiency has become a paramount focus in the cement industry, especially as companies gear up for a significant reduction in energy use by 2025. According to a report by the International Energy Agency (IEA), the cement sector is currently responsible for approximately 7% of global energy-related CO2 emissions. In light of this, there is a pressing demand for innovations that can facilitate a 25% reduction in energy consumption across cement plants. Implementing advanced technologies such as alternative raw materials, improved kiln designs, and innovative heat recovery systems is critical for achieving this ambitious goal.

Recent advancements in process optimization and automation also play a vital role in enhancing energy efficiency. For example, smart manufacturing technologies that leverage artificial intelligence and machine learning can help streamline production processes and reduce waste. The use of predictive maintenance tools can minimize downtime and ensure that equipment operates at peak efficiency. These technological innovations not only contribute to meeting energy reduction targets but also align with the broader industry objectives aimed at promoting sustainable construction practices and lowering the carbon footprint of cement production. As the industry evolves, the commitment to sustainable practices will be essential in addressing climate change and fulfilling regulatory expectations.

Circular Economy in Cement: Strategies for Waste Reduction and Resource Recovery

The cement industry, a significant contributor to global CO2 emissions, is undergoing a transformative shift towards a circular economy. This approach emphasizes waste reduction and resource recovery, essential for sustainable construction practices. Reports indicate that cement production accounts for approximately 8% of global greenhouse gas emissions. To mitigate this, industry leaders are implementing innovative strategies that incorporate recycled materials like industrial byproducts, which not only minimize waste but also reduce reliance on virgin resources. For example, using fly ash and slag in cement mixes can significantly decrease the carbon footprint of concrete.

Tips for companies aiming to embrace circular economy strategies include conducting thorough assessments of available waste materials and establishing partnerships with local industries. These collaborations can effectively turn waste into valuable resources, reducing costs and enhancing sustainability.

Moreover, investing in research and development to explore alternative binders shows promise. Recent studies suggest that innovative materials, such as geopolymer concrete, could lower emissions by up to 80% compared to traditional cement. By actively engaging in resource recovery and optimizing production processes, the cement sector is poised to play a pivotal role in achieving a more sustainable built environment by 2025.

Top Cement Tech Innovations to Watch in 2025 for Sustainable Construction - Circular Economy in Cement: Strategies for Waste Reduction and Resource Recovery

| Innovation | Description | Potential Impact | Resource Recovery Method |

|---|---|---|---|

| Carbon Capture Technology | Innovative systems to capture CO2 emissions during cement production. | Reduction of greenhouse gas emissions by up to 30%. | Utilization of captured CO2 for carbonated concrete products. |

| Geopolymer Cements | Cements formulated from industrial by-products instead of traditional materials. | Decreased reliance on natural resources and lower carbon footprint. | Recovering fly ash and slag from other industries. |

| Smart Cement | Cement that can monitor structural health and respond to environmental changes. | Enhanced durability and safety of concrete structures. | Incorporation of recyclable materials for sensor integration. |

| Waste-Reducing Additives | Additives derived from construction waste to enhance cement properties. | Optimized performance and less landfill disposal. | Recycling of concrete and masonry waste. |

| 3D Printing with Cement | Using cement-based materials for additive manufacturing in construction. | Efficiency in material usage and reduced waste. | Opportunity to recycle existing infrastructure materials into new designs. |

Related Posts

-

What is Cement Tech and How It Revolutionizes the Construction Industry

-

10 Best Cement Tech Innovations Transforming the Construction Industry

-

2025 How to Optimize Portland Cement Production for Sustainable Construction

-

How to Build a Concrete Home That Lasts for Decades

-

Top 5 Benefits of Cement People for Your Construction Projects

-

What is Standard Concrete? Key Properties and Uses Explained

- The Monarch Cement Company

- 449 1200 Street

Humboldt, KS

66748 - (620) 473-2222

- sale@rileydesignbuild.com