Planet

How to Choose the Right Concrete Portland for Your Construction Project

When embarking on a construction project, selecting the correct type of concrete Portland is crucial to ensure the longevity and durability of the structure. According to John Smith, a leading expert in the concrete industry, "The right choice of concrete Portland not only affects the strength and appearance of the construction but also its overall performance in various environmental conditions." Understanding the different formulations, strengths, and applications of concrete Portland can help project managers make informed decisions that align with their specific requirements.

Concrete Portland, known for its versatility and widespread use, serves as a vital component in various construction applications, from residential buildings to large-scale commercial projects. The challenge lies in navigating the myriad of options available in the market, making it essential to consider factors such as the specific structural demands, weather conditions, and the desired aesthetic finish. By delving into the properties and benefits of different concrete Portland types, professionals can tailor their choices to meet the unique needs of their projects, ensuring both functionality and long-term success.

Understanding the Basics of Portland Cement in Construction Projects

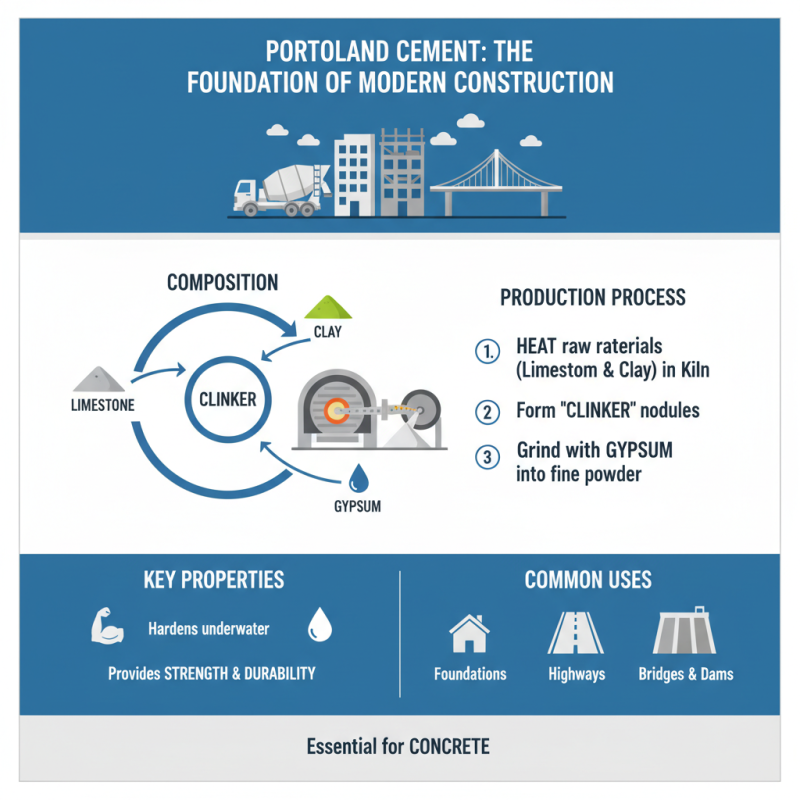

Portland cement is a fundamental ingredient in concrete, playing a crucial role in the strength and durability of construction projects. Understanding its composition and properties is essential for selecting the right type of cement for specific applications. Portland cement is produced from a combination of limestone and clay, which are heated in a kiln to form clinker, then finely ground with a small amount of gypsum. This composition allows it to harden under water, making it ideal for a wide range of construction applications, from foundations to highways.

According to a report by the Global Cement and Concrete Association, the demand for Portland cement is anticipated to reach over 4.5 billion tons by 2050, driven largely by urbanization and infrastructural development worldwide. The report underscores the importance of using quality materials in construction to enhance sustainability and reduce emissions, as Portland cement accounts for approximately 8% of global carbon dioxide emissions. Moreover, understanding the different types of Portland cement, such as ordinary Portland cement and those blended with supplementary cementitious materials, can significantly influence the performance characteristics needed for a specific project. This knowledge helps ensure that construction professionals can make informed decisions, aligning material choices with project objectives and environmental standards.

Evaluating Strength and Durability: Key Metrics for Concrete Selection

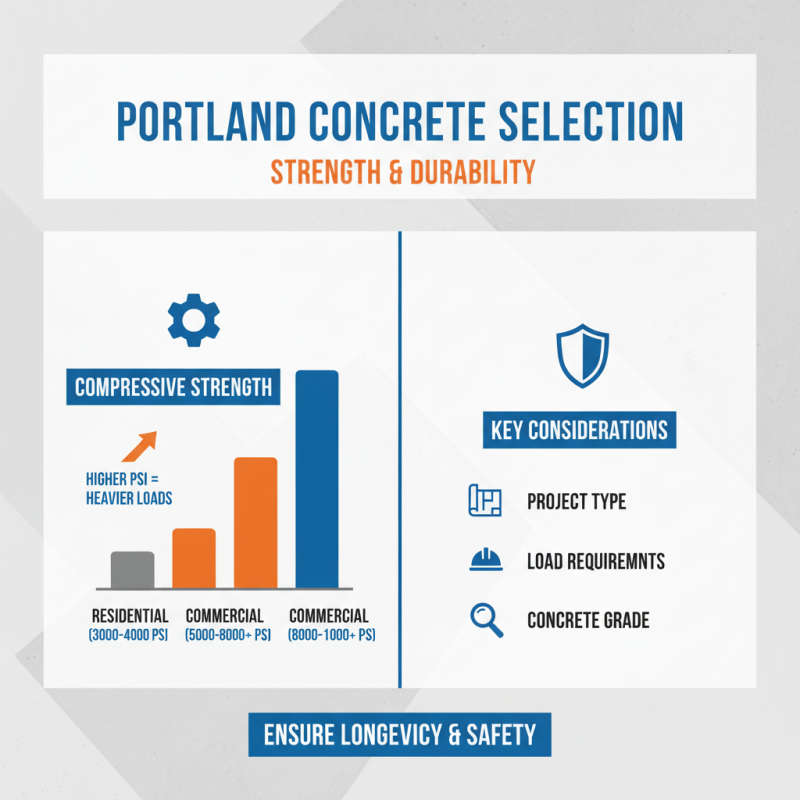

When selecting the right Portland concrete for your construction project, evaluating strength and durability is paramount. Strength is often measured in terms of compressive strength, which indicates the concrete's ability to withstand heavy loads without failing. It's critical to consider the project's requirements; for example, structures like bridges and commercial buildings demand higher compressive strength, often specified in psi (pounds per square inch). Understanding the concrete grade that meets these standards will ensure the longevity and safety of your construction.

Durability, on the other hand, pertains to the concrete's resistance to weathering, chemical attack, and physical wear. Factors such as moisture exposure, freeze-thaw cycles, and salt attack can significantly weaken concrete over time. To evaluate durability, it is essential to examine properties like permeability and shrinkage. A lower permeability indicates better resistance to water and chemical ingress, thereby enhancing the longevity of the structure. Employing additives or selecting specific mixes can further enhance the performance of Portland concrete, ensuring that it can withstand environmental challenges. By carefully analyzing these key metrics, you can make informed decisions that align with the specific needs of your project while ensuring structural integrity.

Assessing Environmental Impact: Choosing Eco-Friendly Portland Cement

When selecting Portland cement for construction projects, environmental impact has become a crucial consideration. The cement industry is responsible for approximately 8% of global CO2 emissions, as reported by the International Energy Agency. This alarming figure has prompted many builders and contractors to seek eco-friendly alternatives that help mitigate environmental degradation without compromising structural integrity. Eco-friendly Portland cement typically incorporates supplementary cementitious materials (SCMs) such as fly ash, slag, and natural pozzolans. These materials can enhance concrete's durability while reducing the carbon footprint associated with traditional cement production.

In addition, life-cycle assessments (LCAs) indicate that using alternative formulations of Portland cement can significantly decrease greenhouse gas emissions. A study by the American Concrete Institute found that implementing eco-friendly practices within the industry could reduce emissions by as much as 25% over the next decade. By choosing mixes containing lower clinker content or utilizing bio-based alternatives, construction projects can contribute positively to sustainable development goals. As demand for green construction grows, it is essential for stakeholders to prioritize materials that not only meet structural requirements but also promote environmental stewardship.

Comparing Different Types of Portland Cement and Their Applications

When selecting the appropriate type of Portland cement for your construction project, it's essential to understand the distinct characteristics and applications of the various types. The primary types of Portland cement are Type I, Type II, Type III, Type IV, and Type V, each tailored to meet specific performance needs. Type I is the most commonly used, suitable for general construction, while Type II provides moderate sulfate resistance, making it ideal for structures exposed to non-severe sulfate conditions. In contrast, Type III is formulated for rapid strength gain, which is advantageous in cold weather construction or when a quick turnaround is necessary.

According to the U.S. Geological Survey, the global production of cement was estimated at around 4.1 billion metric tons in 2021, underscoring the material's significance in the construction industry. Additionally, research indicates that approximately 60% of cement used in infrastructure is Type I, emphasizing its widespread applicability. For projects requiring specialized performance, such as those in marine environments or in the presence of aggressive environmental conditions, Types IV and V offer enhanced durability and protection against sulfates, confirming that the correct choice of Portland cement is crucial for long-term structural integrity. Selecting the right type based on project needs can lead to improved performance and reduced maintenance costs over the structure's lifespan.

Comparison of Different Types of Portland Cement

The Role of Additives in Enhancing Concrete Performance and Longevity

Additives play a crucial role in enhancing the performance and longevity of concrete, particularly in Portland cement applications. According to the American Concrete Institute, the use of chemical and mineral additives can improve various properties of concrete, including workability, strength, and durability. For instance, incorporating superplasticizers can increase the fluidity of the concrete mix without additional water, leading to higher compressive strengths. Studies show that well-designed mixes with superplasticizers can achieve compressive strengths greater than 10,000 psi, compared to typical Portland concrete mixes that often achieve around 4,000 psi.

Moreover, the integration of mineral additives such as fly ash, slag, and silica fume not only enhances the mechanical properties of concrete but also contributes to its longevity by reducing the permeability of the hardened concrete. Research published in the Journal of Materials in Civil Engineering indicates that concrete containing up to 30% fly ash or slag can exhibit improved resistance to sulfate attack and chloride penetration, which are critical factors for infrastructures exposed to harsh environments. This extended durability not only lowers maintenance costs but also extends the service life of structures, making the judicious selection of additives a vital consideration for any construction project.

Related Posts

-

How to Choose the Right Portland Concrete for Your Construction Project

-

Top 10 Standard Concrete Types for Construction Projects You Should Know

-

10 Best Cement Tech Innovations Transforming the Construction Industry

-

Top Benefits of Using Masonry Concrete for Your Construction Projects

-

Understanding the Benefits of American Concrete in Modern Construction Techniques

-

Exploring the Durability of Concrete Houses: Why 70% of Homeowners Prefer This Modern Build

- The Monarch Cement Company

- 449 1200 Street

Humboldt, KS

66748 - (620) 473-2222

- sale@rileydesignbuild.com