Planet

How to Choose the Right Portland Concrete for Your Construction Project

When undertaking a construction project, selecting the appropriate materials is crucial to ensuring durability, structural integrity, and cost-effectiveness. One of the most widely used construction materials is Portland concrete, renowned for its versatility and strength. According to the U.S. Geological Survey, approximately 4.2 billion metric tons of cement were produced globally in 2019, with Portland cement accounting for a significant portion of that figure. This highlights not only the material's popularity but also its importance in the construction industry.

Portland concrete is characterized by its ability to withstand various environmental conditions, making it suitable for a myriad of applications, from residential structures to large-scale infrastructure projects. As per the National Ready Mixed Concrete Association, the use of concrete has increased by 1.7% annually in recent years, emphasizing its critical role in construction trends. However, with the wide array of Portland concrete types and formulations available, choosing the right one for your specific project can be a daunting task. Understanding the nuances of each option, including strength specifications, setting times, and environmental considerations, will aid in making an informed decision that aligns with both project requirements and budget constraints.

Understanding the Different Types of Portland Cement Available Today

Portland cement is a key component in the construction industry, serving as a binding agent in concrete and mortar. Understanding the different types of Portland cement available today is essential for selecting the right material for specific construction projects. The main varieties include Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), and White Portland Cement, each tailored for different applications and environmental conditions. According to the American Concrete Institute, OPC is the most widely used type, accounting for approximately 70% of the total production of cement in the United States.

Portland Pozzolana Cement, on the other hand, incorporates pozzolanic materials such as fly ash or silica fume, enhancing the durability and strength of concrete while reducing the overall carbon footprint. Recent sustainability reports indicate that using PPC can lead to a 30% decrease in greenhouse gas emissions compared to traditional OPC. Additionally, White Portland Cement, known for its aesthetic appeal, is primarily used for architectural finishes and artistic applications, where color and brightness are critical.

As the construction industry continues to evolve, selecting the appropriate type of Portland cement can significantly impact the performance and sustainability of building projects.

Key Factors to Consider When Choosing Portland Cement for Your Project

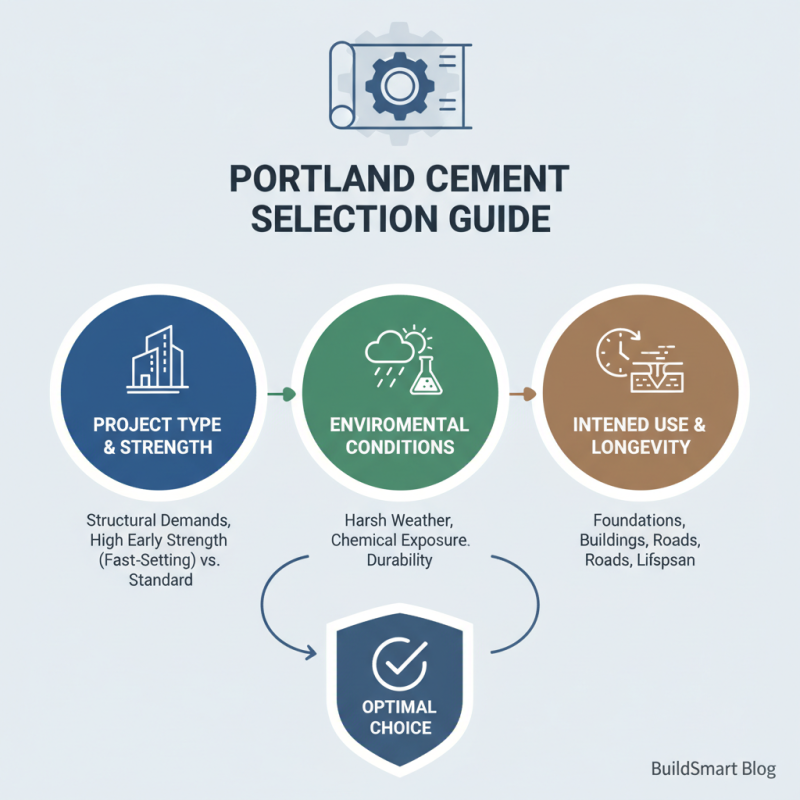

When selecting the right Portland cement for your construction project, several key factors come into play. First, consider the specific requirements of your project, including the structural demands and environmental conditions. For instance, some projects may require high early strength, making fast-setting varieties more desirable, while others might benefit from cements with enhanced durability to withstand harsh weather or chemical exposure. Understanding the intended use and longevity needed will help narrow down the options.

Another significant factor is the type of aggregates you plan to use, as compatibility between cement and aggregates is crucial for achieving optimal performance. The water-cement ratio also plays a vital role; maintaining the right ratio is necessary to ensure the strength and workability of the concrete mix. Additionally, take into account any specific certifications or standards that may apply to your project, as compliant materials help ensure quality and reliability in your construction process. By carefully assessing these factors, you'll be better equipped to choose the most suitable Portland cement for your needs.

Evaluating Strength Requirements Based on Structural Specifications

When selecting Portland concrete for your construction project, it is imperative to evaluate the strength requirements based on your structural specifications. Understanding the compression strength needed for the concrete is crucial, as it directly impacts the durability and longevity of the structure. Common strength ratings, such as 3,000 psi or 5,000 psi, serve as benchmarks for different types of construction applications. For instance, residential foundations may require lower strength ratings, while high-rise buildings or bridges necessitate higher specifications to sustain greater loads and stresses.

When selecting Portland concrete for your construction project, it is imperative to evaluate the strength requirements based on your structural specifications. Understanding the compression strength needed for the concrete is crucial, as it directly impacts the durability and longevity of the structure. Common strength ratings, such as 3,000 psi or 5,000 psi, serve as benchmarks for different types of construction applications. For instance, residential foundations may require lower strength ratings, while high-rise buildings or bridges necessitate higher specifications to sustain greater loads and stresses.

Additionally, factors such as exposure conditions and environmental influences play a significant role in determining concrete strength requirements. In areas prone to extreme weather or high moisture, selecting a mix with enhanced durability properties can prevent issues related to cracking or degradation over time. Furthermore, consulting with structural engineers during the design phase helps ensure that the chosen concrete mix aligns with the overall design goals and safety regulations, providing peace of mind that the foundation will support the intended use over its lifespan.

Environmental Impact: Selecting Sustainable Portland Cement Options

When choosing Portland cement for your construction project, it's essential to consider the environmental impact of various options. Traditional cement production is known for its high carbon emissions, contributing significantly to global climate change. However, the industry is evolving, and sustainable alternatives are gaining traction. These eco-friendly options often incorporate recycled materials or utilize innovative technologies that reduce the energy required for cement production. By selecting these sustainable Portland cement varieties, builders can significantly lower the carbon footprint of their projects.

Additionally, look for certifications indicating lower environmental impacts, such as those that demonstrate reduced emissions during production or emphasize the use of materials sourced from local suppliers. This not only supports sustainable practices but also encourages local economies. In taking these steps to select sustainable Portland cement, construction professionals can play a pivotal role in promoting environmental stewardship while still meeting the structural requirements and performance standards of their projects. Adopting sustainability in cement choices is not just a trend; it represents a commitment to responsible construction that benefits both present and future generations.

How to Choose the Right Portland Concrete for Your Construction Project - Environmental Impact: Selecting Sustainable Portland Cement Options

| Cement Type | CO2 Emissions (kg per ton) | Recycled Material Content (%) | Water Use (liters per ton) | Durability Rating |

|---|---|---|---|---|

| Ordinary Portland Cement | 900 | 5 | 200 | Medium |

| Reduced Emission Cement | 600 | 20 | 150 | High |

| Fly Ash Cement | 520 | 30 | 170 | Very High |

| Slag Cement | 550 | 40 | 180 | Very High |

| Natural Pozzolan Cement | 650 | 25 | 160 | High |

Cost Analysis of Various Portland Cement Types for Budgeting Purposes

When embarking on a construction project, a crucial factor to consider is the cost analysis of different types of Portland cement. The costs of cement can vary significantly based on the type chosen, which can affect overall project budgeting. Factors influencing cement prices include raw material availability, production methods, and transportation expenses. Different types of Portland cement, such as ordinary Portland cement (OPC), sulfate-resistant cement, and high early strength cement, come with unique pricing structures based on their composition and intended use.

Understanding these costs is essential for making informed decisions. For instance, while ordinary Portland cement might be the most economical choice for general applications, specialized types may offer benefits that justify their higher price. For example, sulfate-resistant cement, though more expensive, can save costs in long-term durability for structures exposed to harsh environments. Analyzing the project requirements against the budget allows for a strategic selection that balances initial costs with long-term performance and maintenance expenses, ultimately leading to a more cost-effective construction outcome.

Cost Analysis of Various Portland Cement Types

Related Posts

-

Top 10 Benefits of Using Mixed Cement for Your Construction Projects

-

Understanding the Benefits of American Concrete in Modern Construction Techniques

-

Exploring the Durability of Concrete Houses: Why 70% of Homeowners Prefer This Modern Build

-

Why You Should Choose Masonry Cement for Your Next Construction Project

-

2025 How to Optimize Portland Cement Production for Sustainable Construction

-

2025 How to Choose the Best Cement Maker for Your Construction Needs

- The Monarch Cement Company

- 449 1200 Street

Humboldt, KS

66748 - (620) 473-2222

- sale@rileydesignbuild.com